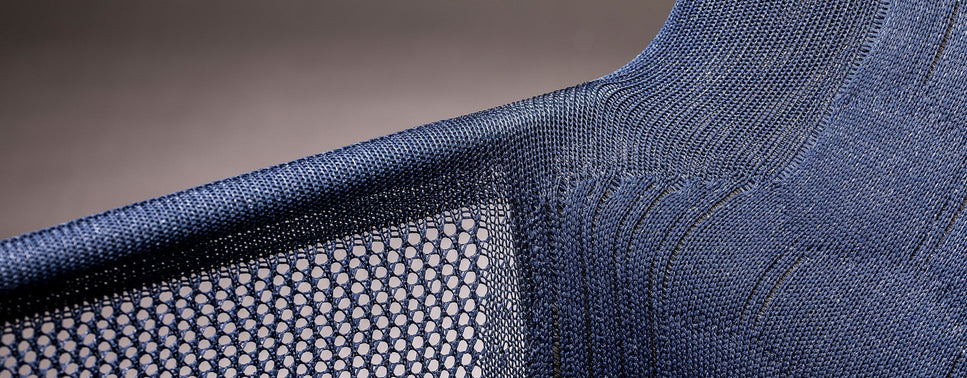

3D KNITWEAR

We are at the forefront of a long overdue fashion industry shift to digital production.

What is 3D Knitwear ?

Similar to 3D printing, our machines create your garment in one seamless piece, with no cutting or textile waste. By contrast, most companies are still using multiple step assembly-line methods. This process wastes up to 35% of the yarn and is so labour intensive that in order to be profitable, workers are often paid unfair wages in unregulated conditions. We want to change these industry standards.

Our Story

Based in Montreal, Canada, we are named for the revolutionary architect and designer Joseph Maria Olbrich.

Aiming to change the way clothing has traditionally been made, the brand is continually inspired by the pivotal moment in design history when Olbrich and Gustav Klimt founded the Vienna Secession collective. This group of artists and designers came together in protest of outdated production methods and changed the design world.

Olbrich is proud to be independently owned and operated. Founder and Creative Director Rebecca Lemire comes from a background as an Architectural Historian. She applies her interest in modernist design to the styles she creates for Olbrich.

Image: Vienna Secession Hall, Architecture by Joseph Maria Olbrich. Frieze by Gustav Klimt, c.1901.

Sustainable Benefits

Zero Textile Waste: In traditional cut-and-sew knitwear, up to 35% of the yarn is wasted in the cutting process, but with 3D knitwear all of the yarn goes directly into the garment itself.

Massive Reduction in Sampling Waste: Traditional sampling usually involves the international shipment of 3-4 pieces between the designer and manufacturer. 3D knitwear only requires 1 or 2 samples and our manufacturer is just a few hours drive from our studio.

Local Production: Our products are designed in Montreal and manufactured in Brooklyn, New York. By keeping our production local we are significantly reducing our use of transport-based fossi fuels.